Vinegar fermentation is the process by which ethanol (alcohol) is converted into acetic acid and water by acetic acid bacteria. It is commonly used in cooking, pickling, and as a condiment.

- The science of fermentation in vinegar production is converting sugar into alcohol and then into acetic acid by microorganisms.

- The role of microorganisms in Vinegar fermentation depends on the activity of yeast and acetic acid bacteria.

- The importance of food preservation clarifies how traditional methods of food preservation have evolved, and vinegar helps to increase the shelf life of food.

- Vinegar has various applications in various industries, including food, cleaning, and industrial production.

- Vinegar fermentation can be a sustainable process that utilizes natural microorganisms and does not require high energy inputs.

Interesting Science Videos

Vinegar Fermentation Process

In the process of fermentation, microorganisms play a vital role. Humans have used natural fermentation from ancient times to develop many products, foods, medicines, and fuels.

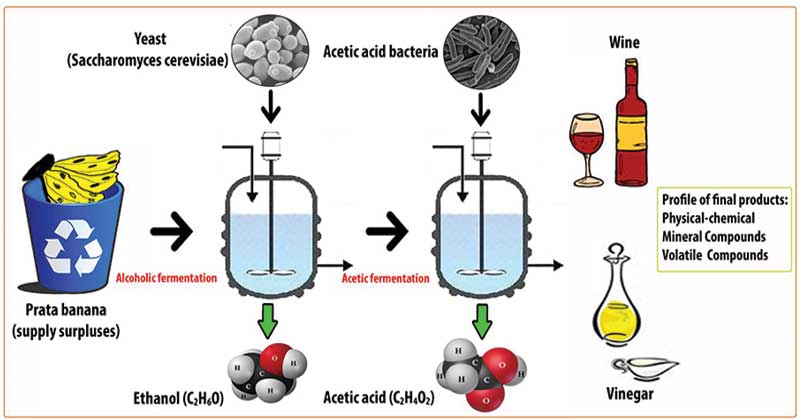

Vinegar is produced through a two-step fermentation process. The first step is alcoholic fermentation which involves the conversion of sugar into alcohol and carbon dioxide by yeasts. The second step is acetic acid fermentation, where acetic acid bacteria ferment the alcohol to produce acetic acid and water. During the process, the bacteria consume oxygen and produce carbon dioxide that causes the vinegar to be bubbly and fizzy often.

Further, vinegar has a wide range of applications in several industries. Also, vinegar is a common preservative in the food industry and a standard household cleaner in producing pharmaceuticals, cosmetics, and other industrial products.

Alcoholic Fermentation

Alcohol fermentation is a process that involves the conversion of sugars into ethanol and carbon dioxide by yeast. It is an anaerobic process that occurs in the absence of oxygen. Further alcoholic fermentation is a necessary process in the manufacturing of alcoholic beverages and the production of biofuels.

In alcoholic fermentation, yeast consumes sugar and breaks it into two pyruvate molecules. Later the pyruvate is converted into ethanol and carbon dioxide through fermentation, producing a small amount of energy in the form of ATP.

Alcoholic fermentation follows the enzymatic pathway similar to glycolysis. The two enzymes, pyruvate decarboxylase and alcoholic dehydrogenase, convert pyruvic acid into carbon dioxide and ethanol in alcoholic fermentation.

Glucose → 2 pyruvate → 2 ethanol + 2 CO2 + energy (ATP)

Moreover, the rate of alcoholic fermentation can be influenced by several factors, including temperature, pH, oxygen availability, and the concentration of yeast and sugar; a higher concentration of yeast and sugar can result in faster fermentation, while a lower temperature can slow down the process.

Factors Affecting Alcohol Fermentation

- Fermentation may slow down or stop if the temperature is low, whereas yeast may damage if the temperature is high.

- The amount of sugar in the mixture of fermentation can affect the process. If the sugar concentration is high, fermentation is slow, while the sugar-resulting product is weak if the sugar concentration is low.

- The pH level, whether too high or low, can slow the fermentation process.

- Oxygen is required for the fermentation process, but too much can inhibit the fermentation process.

Production of Vinegar

Vinegar production involves the conversion of alcohol into acetic acid and water through the process known as acetic acid fermentation. The primary biochemical process is biological oxidation, in which alcohol is partially oxidized to vinegar by acetic acid bacteria with two sequential enzymatic reactions alcohol to acetaldehyde and acetaldehyde to acetic acid.

During the process, ethanol is oxidized to acetaldehyde by pyrroloquinoline-dependent alcohol dehydrogenase(ADH), and acetaldehyde is oxidized to acetic acid by aldehyde dehydrogenase (ALDH). The enzymatic activity of ADH and ALDH affects the acetification reaction in acetic acid bacteria. These enzymes deal with regulatory sites to enhance vinegar productivity by acetic acid bacteria.

Differences in flavor, color, and acidity of vinegar

Vinegar can be produced from various sources, resulting in different types of vinegar with unique flavors, colors, and acidity levels. Other types of vinegar based on the source material used are

Wine vinegar: Made from red or white wine with moderate activity or fruity flavor.

Apple cider vinegar: Made from apple cider with a tangy and slightly sweet flavor.

Balsamic vinegar: Made from vinegar which has a sweet and complex flavor

Rice vinegar: Made from fermented rice, which has a mild flavor

Generally, vinegar has a sour taste due to its high acidity level, but the flavor can range from mild to intense. Vinegar color can vary from clear to dark brown depending on the source material and aging process. The acidity level of vinegar can range from 4% to 7% or higher, with some types of vinegar having a higher acidity level than others.

The “mother” is a term used to describe the cellulose and acetic acid bacteria that form a cloudy substance in raw, unpasteurized vinegar. This substance is harmless and is considered beneficial, as it contains enzymes and beneficial bacteria that may help improve digestion and boost immunity.

Conclusion

The production of vinegar has a significant impact on various industries, such as food, health, and cleaning. Vinegar is commonly used in cooking, salad dressings, marinades, and as a health supplement. Raw, unpasteurized vinegar also contains beneficial bacteria and enzymes that can help improve digestion and boost immunity.

Further research and development in vinegar fermentation can lead to the discovery of new and innovative types of vinegar with enhanced flavors and health benefits. It is an exciting area of research that has the potential to contribute to the growth of the food and health industries.

References

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8145929/#:~:text=Vinegar%20is%20produced%20through%20a,by%20bacteria%2C%20generally%20Acetobacter%20species.

- https://ucfoodsafety.ucdavis.edu/sites/g/files/dgvnsk7366/files/inline-files/192137.pdf

- https://www.icr.org/article/glycolysis-alcoholic-fermentation/

- https://link.springer.com/article/10.1007/s00253-015-6659-1

- https://ift.onlinelibrary.wiley.com/doi/abs/10.1111/1750-3841.12434

- https://www.jstage.jst.go.jp/article/bbb1992/61/1/61_1_138/_article/-char/ja/

- https://www.mdpi.com/214922

- https://www.scielo.br/j/bjm/a/3bF9qyC65ncRBbX4HZR4tLk/?format=html&lang=en