Beer is used as an alcoholic beverage across the world. Beer comes third in the world’s most popular drinks after water and tea because of its unique, distinctive taste, smell, and appearance. The composition of chemical compounds determines the taste, color, and smell of the beer. Beer is mostly 90% water with mineral ions, and the rest is composed of organic compounds like carbohydrates and aromatic molecules. Beer is often referred to as the ‘liquid bread,’ containing a rich array of micronutrients such as magnesium, vitamin B, biotin, potassium, phosphorus, and many more. Beer also contains phenolic acids such as vanillic acid, 4-hydrophenylacetic acid, etc. They also contain 8-prenylnaringenin, a phytoestrogen derived from the hops flower, responsible for the bitter taste and the unique aroma.

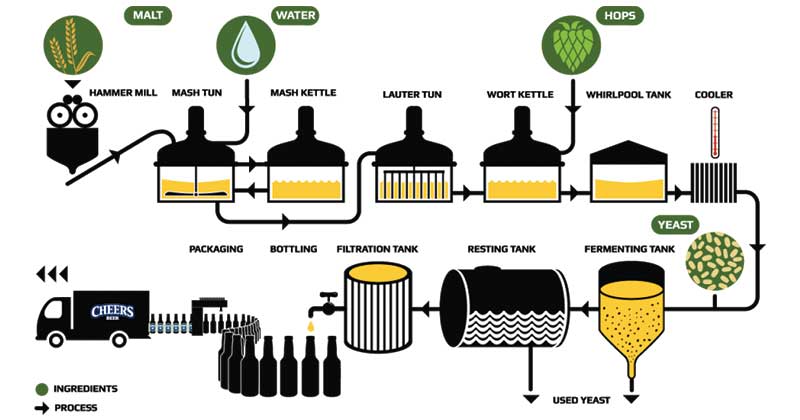

Beer is produced by the process of brewing and fermentation of starch present in the grains such as malted wheat, rice, maize, and oats. Beer can also be produced at home via a home brewer. The fermentation of the starchy sugars by the yeast results in ethanol production and carbonation in the final product. Most modern beers have hops as an additive that acts as a stabilizing agent and preservative, giving the beer a distinctly bitter flavor. The brewing and fermentation process comprises a minimum of ten processing steps from malted barley or any other grain to the finished product.

Interesting Science Videos

Beer Production History

Beer is considered to be one of the oldest alcoholic drinks, as the evidence presents. The production process of beer making is so simple that it led to its invention and popularization. Since any sugar (starch) containing substance can undergo alcoholic fermentation, many cultures quickly adopted and invented beer as a sweet liquid.

- The earliest known archaelogical fermentation evidence is of 13,000-year-old beer residue used by the semi-nomadics of the Raqefet cave of Carmel mountains in many ritual feasting of Israeli culture.

- The famous hymn of the Sumerian culture, ‘The Hymn of the Ninkasi,’ served as a prayer and a method to remember the beer recipe by the few literate people.

- The brewing technique landed the European territories around 3000 BC. Primary fermentation was performed in almost every household.

- European beer contains fruits, herbs, and spices to add extra flavor. And with Industrial Revolution, Beer production gained widespread mass production across the world.

Beer Production Raw Materials-Ingredients

Any beer type has four key raw materials or ingredients for the manufacturing process. They are malt, water, yeast, and hops. These ingredients regulate the taste, aroma, and color of the finished beer.

Water-Major Raw Material

Water constitutes around 90% of beer composition. Modern technologies are allowed to modulate the concentration of salts and mineral ions with very high precision.

- Ideally, water is flavorless, but the bicarbonate ions as a dissolved mineral contribute to the finished beer’s taste.

- The water used in brewing has to be pure, potable, and free of pathogens, which are easily obtained and analyzed by chemical and microbial processes.

- The brewing water from a particular region specifies the type of beer from that region due to the difference in the composition of salt concentration and mineral ions.

- Guinness is made from Germany’s hard water (high in salt constituents), while the Pilsner is made from water with low salt contents found in the Czech Republic.

Starch Source – Grain Malt

The starch source is usually obtained from the malting of germinated seeds. The malting process is done by soaking the grain seed (barley, wheat, rice) in the water for it to germinate and then allowing the partially germinated grain to dry in a kiln.

- The malted grain undergoes a chemical reaction of the starch being converted to fermentable sugar due to the presence of enzymes released during malting.

- The grain malt is the key material that determines the flavor and strength of the beer; hence different types of grain can produce beer with differentiating flavors.

- Wheat malt has more protein and gives a more foamy head with a fuller taste. On the other hand, corn malt brings lighter beer with decreased haziness and enhanced flavors, thus giving more neutral sweetness to the beer.

Hops – Additive

Flowers of hops are widely used in Modern Beer production. They are responsible for the bitterness (balancing the sweetness of the malt) and act as a preservative agent.

- The presence of essential oils in the hops flower gives beer its unique aroma.

- They have more than 200 substances, such as resins, polyphenols, and flavoring agents, contributing to the beer’s taste.

- The cones present in the pistillate hop plant can only be used for beer production. Alpha acids and their derivatives present in hops show a significant bittering potential and preservative effect.

- While resins in hops enhance the physiological digestibility, stability of foam created by carbonation, and antibiotic properties that otherwise may favor the growth of less desirable micro-organisms.

- The quality of the beer is influenced by the presence of polyphenols such as xanthohumol, which acts as an anticarcinogenic agent.

Yeast – Fermentation Agent

The microorganism used for the fermentation of the wort produced in beer production. Yeast family Saccharomycetaceae is favored as brewer’s special yeast. Yeast is responsible for the production of alcohol and carbon dioxide by metabolizing the sugar extract obtained from the grain malt or wort.

- Two dominant types of yeast fermentation methods are widely used for beer manufacturing: top fermentation and bottom fermentation.

- In the top fermentation technique, the yeast extract is layered on the surface of the malt. The most favored yeast organism for this technique is Saccharomyces cerevisiae, which is cultivated at 15-26 degree Celsius.

- In bottom-fermenting, the yeast extract is layered at the bottom of the beer must. Saccharomyces pastorianus is the yeast organism used in bottom-fermenting, which is cultivated at 8-14 degrees Celsius.

Beer Production Process – Malting and Brewing

The main objective of beer making process, which involves lots of steps, is to convert the grain starch from germinated seeds to the sugar and extract this sugar via water, and then let it ferment with yeast to obtain the final product of an alcoholic, carbonated drink. The steps generally involve: Malting, milling, mashing, extract separation, hop addition and boiling, removal of hops and precipitating it, cooling and aeration, fermentation, separation of yeast from young beer, aging, maturing, and packaging.

Malting Process

Malting process is called the ‘Artificially Induced Germination of Crop.’ The malting process involves the ‘steeping and aerating’ step, allowing the seed grain to germinate, dry, and curing of malt. The protein content required for conventional beer is estimated to be 11-11.5%, as seen in barley. Since barley has higher protein content, it leads to the colloidal instability of beer. Heterogenous beer can cause problems during manufacturing, leading to reduced quality beer. Heterogenous malting is a mixture of malt composed of different grain sizes. Increased protein content can be seen in small grains, germinating faster than the larger ones.

Steeping

The first step begins with barley immersed in water. Barley has to be harvested at a moisture of 12% in water at 12-15 degree celsius for 40-50 hours.

- As the grain soaks in water, the volume increases by 25%, and the moisture content reach around 45%.

- Barley grain has a white root sheath called chit, and during the steeping period, chit breaks through the husk.

- The chitted barley is then extracted from steep for germination. During this step, the barley grain is drained and allowed to have air rests.

Germination

Any grain seed needs a sufficient amount of heat, oxygen, and humidity to germinate.

- The temperature range for germination is between 14-18 degree Celsius.

- The steeped grain is placed in heaps for 24 hours according to the traditional malting and spreading onto a floor for germination.

- Germination allows the formation of highly active alpha- and beta-amylases and other protease enzymes.

- These enzymes help in the conversion of complex sugars (like glucans) and insoluble proteins to soluble glucose and amino acids. As the germination proceeds, greater enzymatic reactions occur.

Kilning of Malt

This step removes water and fixes any substantial translations, producing a typical color and aroma in a beer. Drying green malt helps to remove moisture and arrests 30-40% of enzyme activity. Kilning is subdivided into two steps – withering and curing.

- Withering reduces the water content from 45% to 10% in the green malt at low temperatures.

- Curing is done at a temperature range between 80 to 105 degrees Celcius. Higher temperature curing gives the malt its dark color (due to a reduction in the amount of dimethyl sulfite) and aroma.

- At a temperature below 40 degrees Celcius, with water content above 20%, it is referred to as the Growing phase. There is a dissolution of grain and an increase in the amount of degradation by enzymes.

- At temperatures between 40-70 degrees, due to an increase in enzymatic dissolution and enhanced degradation, this is referred to as the ‘Enzymatic Phase.’ Eventually, degradation comes to a halt as the water content decreases, resulting in the discontinuation of the embryo’s growth and accumulation of degradation products.

- Radicals must be removed during kilning as it absorbs water, causing increased coloring and bitterness.

Malting Adjunct – A protein present in the grains, especially barley, must be diluted by adding any starch or sugar material called malt adjunct, which includes ‘dextrose sugar syrup.’

Brewing Process

There are several steps involved in this process which include:

Milling

The process of milling refers to crushing dried barley grains between rollers to produce a coarse powder called Grist. The quality of milling affects the further steps of mashing and lautering, hence regulating the finished beer quality. Finely milled malt helps enhance enzymatic reactions due to increased surface area, making the ingredients easier to dissolve.

Mashing

The grist obtained in the milling process is mixed with warm water and is maintained at 62-70 degrees Celsius. The enzymatic conversion of starch to simple sugars is hydrolyzed by an amylase enzyme, and protein to smaller peptides and amino acids is completed in mashing. pH and temperature determine the degree of enzymatic hydrolysis.

Amylolysis – Amylose and amylopectin present in starch dissolve in three steps –

- Gelatinization – During gelatinization, starch molecules absorb water. At 60 degrees, starch from malt gelatinizes in the presence of an amylase enzyme.

- Liquefaction – Digestion of gelatinized starch is done by amylases, by splitting alpha-amylase to 1,4 bonds of amylopectin and amylose. As the starch molecules are digested, viscosity decreases, allowing beta-amylase to react to the newly formed molecules.

- Saccharification – The dextrin molecules present in the malt are reduced to maltose in this step. Alpha-amylase shows optimum enzyme activity at 57-65 degrees, while beta-amylase shows enzyme activity at 70-75 degrees Celsius.

Proteolysis – The breakdown of proteins into smaller peptides and amino acids is referred to as proteolysis. Two enzymes – endo- and exo-peptidases determine the nature of peptides formed.

- Endopeptidase – Cleaves the protein between the molecule resulting in the increase in soluble nitrogen content.

- Exo-peptidases – Cleaves the protein chain at the ends, forming free amino acids.

- Proteins degrade and precipitate at temperatures of 45-55 degree celsius due to changes in pH.

- The breakdown of peptides is a necessary determinant of the flavor and foam formation in beer.

Cytolysis – Hemicelluloses present in the cell wall are degraded, which leads to an increase in the viscosity of the malt. The degradation process occurs at temperatures below 50 degrees, and with an increase in temperature, breakdown decreases.

Wort Preparation – Mash is prepared in the mash tun, a special mashing container.

- The addition of water leads to increased enzymatic reactions.

- High short mashing procedure – where the mash is maintained at 60-65 degrees temperature for 30-45 minutes.

- Then the mash is further heated at a rate of 1 degree Celsius per minute till 72 degrees.

- Until iodine normality is reached, rest is retained in the mash.

- As a result, we obtain a liquid called Wort, which is approximately 10% sugar, and the rest is other organic molecules such as carbohydrates, proteins, etc.

Lautering – Wort Separation

The objective of lautering is the separation of wort liquid and solid grist in a lautering container called lauter tun. Grain husk is used as a filter in this procedure.

- Wort liquid is drained out first, with an extract content of 16-20%.

- Then, the residual grist is flushed through hot water several times with an extract concentration of 0.5-1%, referred to as the ‘Last Runnings.’

- Temperature plays an important role in lautering as the temperature is raised, viscosity decreases, which leads to lautern acceleration. But temperature above 80 degrees is observed to be unfavorable as the alpha-amylase loses the enzyme activity to reduce starch.

- The first wort runoff consists of a lot of particles, so it is placed in lauter tun, and water is continuously being added till the last run.

- Propylene sheets are used to separate wort and spent grist in a mash filter.

Wort Boiling – Hops Addition

After separation, the extracted wort is transferred to a Kettle, a copper vessel for wort boiling. This step is important to halt the enzyme activity and to get the bitterness from the hops flower.

- Hops and other liquid sugar adjuncts, such as corn syrup, dextrose, etc., are added to the wort for boiling together.

- The objective of boiling wort is to evaporate excess water, adjust extract content, enhance flavors, formation of color, isomerization of bitter substances in the hop, flocculation (precipitation of proteins), sterilization of wort, and inactivation of enzymes.

- Precipitated proteins and hop particles, called ‘Hot Trub’, are removed after boiling.

- To minimize the infection risk, the wort has to be cooled down as quickly as possible.

- The temperature required for bottom fermentation is 5-10 degrees, and for top fermentation is 15-25 degree Celsius.

Fermentation by Yeast

The yeast strain required for fermentation is Saccharomyces pastorianus and S. carlsbergens as the bottom yeast and Saccharomyces cerevisiae as the top yeast. Yeast cells inoculum is recovered from the previous fermentation tank and treated with tartaric acid and phosphoric acid, which reduces the pH and removes any bacterial contamination.

- Yeast of 0.3 kg per hectolitre of wort is mixed.

- It is usually maintained at 3-4 degrees Celsius for 14 days.

- Yeast converts sugar into alcohol and carbon dioxide (CO2) during fermentation, with a small amount of acetic acid and glycerol.

- In a Closed Fermenter Tank, the liberated CO2 from fermentation is collected and used up in the carbonation process.

- By the 5th day of fermentation, maximum Co2 is liberated, and there is no CO2 evolution by 7-9 days because yeast cells flocculate as they become inactive.

- Beer mostly contains 3.5-5% alcohol content.

Maturation and Carbonation

The young green beer produced is stored at 0 degree Celsius for several weeks to months. During this period, yeast, resin, proteins, and any other undesirable substances precipitate, and the beer becomes clear. During maturation, the production of ester and its derivatives contributes to the beer’s taste and aroma.

Beer is carbonated by CO2 after aging.

Pasteurization, Filtration, and Packaging

Pasteurization are done at a temperature of 60 degrees Celsius to inactivate yeast and any spoilage microorganism to prevent further alcohol production. Pasteurization helps in extending the shelf life of beer at room temperature.

Filtration after maturation helps remove any small or large particles that might be left in the foamy beer that is transparent and ready for packaging.

For Packaging, different kinds of containers, such as kegs, bottles, barrels, etc., are washed thoroughly and pasteurized at 60-65 degrees Celsius. Remove any air present inside the containers, as Beer is a short-life beverage that requires sterile conditions for storage.

Beer Production By-products and Waste Recycling

Beer manufacturing produce several byproducts and wastes that can be utilized by other industries.

- During the malting of grains, rootlets discarded from the grains can be collected and used for animal feeding.

- Hops retained from the finished wort are utilized as a fertilizer for the crops.

- The residual yeast retained from the brewing process is a rich source of vitamin B which can be used by pharmaceutical industries to produce drugs, vitamin capsules, or as a food additive.

- Used beer bottles and cans are routinely collected and recycled.

Beer and Health

The studies show varied viewpoints on the consumption of beer. The data collected and the results obtained have many variables to consider regarding the health effects of beer consumption. The effects also depend on the region, lifestyle, and socioeconomic status of the person. Higher consumption of beer can develop the issue of alcoholism, which is seen to reduce the life expectancy of a person by around 10 years, making it the 3rd leading cause of early death in the United States. Although, moderate consumption of Beer has no relation to mortality and abdominal obesity. In men, moderate consumption has been associated with a decrease in diabetes. A condition of Beer Belly is caused due to lack of muscle tone, a stagnant lifestyle, overeating, and not due to beer consumption. Overall, the effect of beer on health depends on many factors, including the quality of beer consumed, besides the individual’s health status.

Beer Production and Environmental Effects

With the increase in the consumption of beer worldwide, the goal of reaching sustainable development by the manufacturing industries and the consumer becomes a priority. Regulation of raw materials used in beer manufacturing is modulated to avoid any unbalanced utilization of natural resources. The raw materials used in packaging elements such as beer cans, and bottles, harvesting elements like fertilizers and pesticides, as well as transport elements which includes petroleum fuels and toxic gases released by vehicles, are the major factors contributing to the negative effects of sustainable development. Along with the mentioned elements, the thermal energy released during the malting and brewing process of beer production also contributes to the opposite aspect of sustainable development. Therefore, improvements in these areas of interest should be a priority for more respectful behavior toward the environment.

Conclusion

Beer is the third most consumed drink in the world, which is an alcoholic beverage. Due to the popularity of beer, they are sometimes referred to as the ‘Liquid Bread.’ Beer has a sweet taste with a strong flavor, bitter taste, and distinct aroma. Beer contains 93% water; the rest are alcohol, essential oils, vitamins, carbohydrates, etc. Regular beer has 4.5 – 5% alcohol content, as per the rules. The manufacturing process involves numerous simple processes such as steeping, lautering, fermentation, and more, which are keenly maintained at particular temperatures and pH. The beer is made from the malting of grains seeds of barley, oats, rice, and wheat. Each grain malt has a different taste, contributing to different types of beer. The water used in the production process also contributes to the taste of the beer, hard water is used in Guinness beer, and soft water is used in Pilsner beer. Not many health benefits are observed, though, in some men, it has been shown to decrease diabetes. To contribute to a healthy environment, industries and consumers should equally participate in the objective of sustainable development.

References

- Beer chemistry – https://en.wikipedia.org/wiki/Beer_chemistry

- Beer – https://en.wikipedia.org/wiki/Beer

- Beer alcoholic beverage – https://www.britannica.com/topic/beer

- 9 Important Grains That Affect the Flavours of Beer – https://londonbeercompetition.com/en/blog/insights-1/9-important-grains-that-affect-the-flavours-of-beer-64.htm

- Bamforth, C. W. “Progress in brewing science and beer production.” Annual Review of Chemical and Biomolecular Engineering 8 (2017): 161-176.

- Hospido, Almudena, Maria Teresa Moreira, and Gumersindo Feijoo. “Environmental analysis of beer production.” International journal of agricultural resources, governance and ecology 4.2 (2005): 152-162.

- What Is A Standard Drink? – https://www.niaaa.nih.gov/alcohols-effects-health/overview-alcohol-consumption/what-standard-drink

- Milani, Elham A., and Filipa VM Silva. “Pasteurization of beer by non-thermal technologies.” Frontiers in Food Science and Technology 1 (2022): 2.

- Marcos, Ascensión, et al. “Moderate consumption of beer and its effects on cardiovascular and metabolic health: An updated review of recent scientific evidence.” Nutrients 13.3 (2021): 879.

Very good write up.

Best wishes.