A hot air oven is an essential laboratory equipment that uses to dry heat (hot air) to sterilize laboratory objects and samples. This type of sterilization is also known as dry heat sterilization.

This mechanism of heat treatment was introduced by French scientist Louis Pasteur in the late 1800s where he used dry heat for a brief period of time to kill off harmful microorganisms from the wine without altering its taste.

A hot air oven is generally used for samples that are heat resistant and do not melt, change the form or catch fire on exposure to high temperatures. It generally kills microorganisms and bacterial spores at extremely high temperatures over several hours and sterilizes items. Effective sterilization can only be achieved when the appropriate temperature and holding time are selected depending on the type of microorganism being targeted and the type of material being sterilized. The most commonly used temperature and time to sterilize items are 170 degrees Celsius for 30 minutes, 160 degrees for 60 minutes, and 150 degrees for 150 minutes.

Interesting Science Videos

Principle of Hot Air Oven

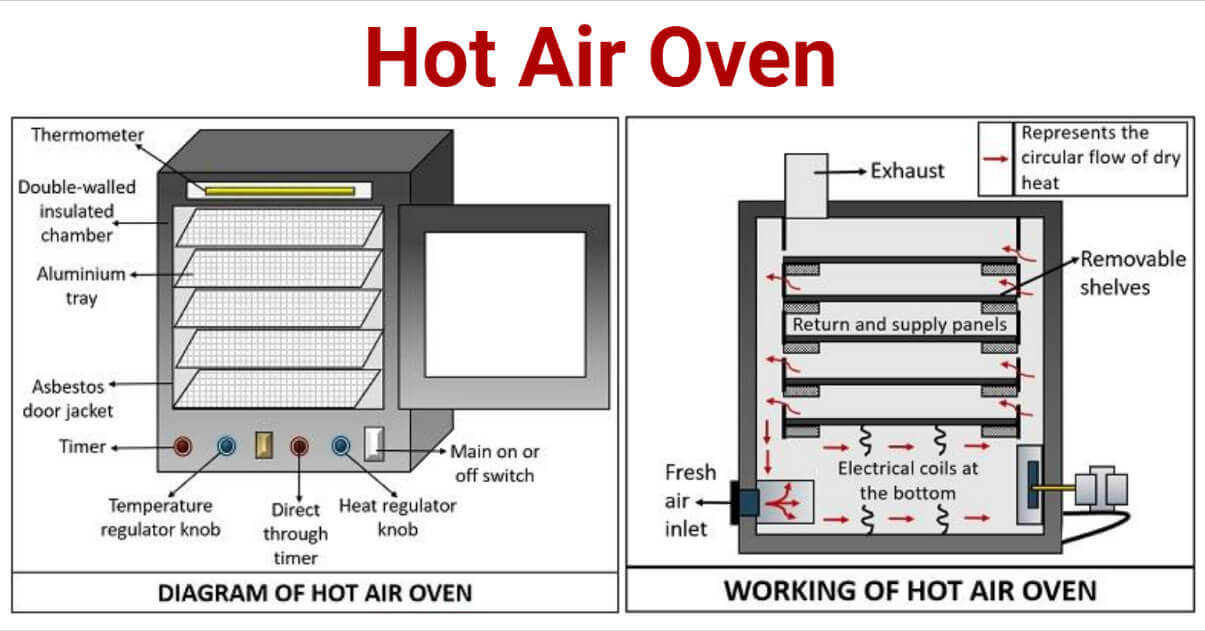

Hot air oven works on the principle of the dry air sterilization process through convection, conduction, and radiation. The heating elements heat the air inside the chamber, which may be circulated evenly within it with the help of fans such that the sample surfaces are exposed to hot and dry air. This exposure causes the heating of the external surface of items, and by the conduction process, the heat is transferred toward the center of the item. Likewise, in microorganisms, heat causes water inside them to evaporate, causing oxidative damage of cellular constituents, denaturation of proteins, and toxic effect of elevated levels of electrolytes and, ultimately, the death of the microorganisms.

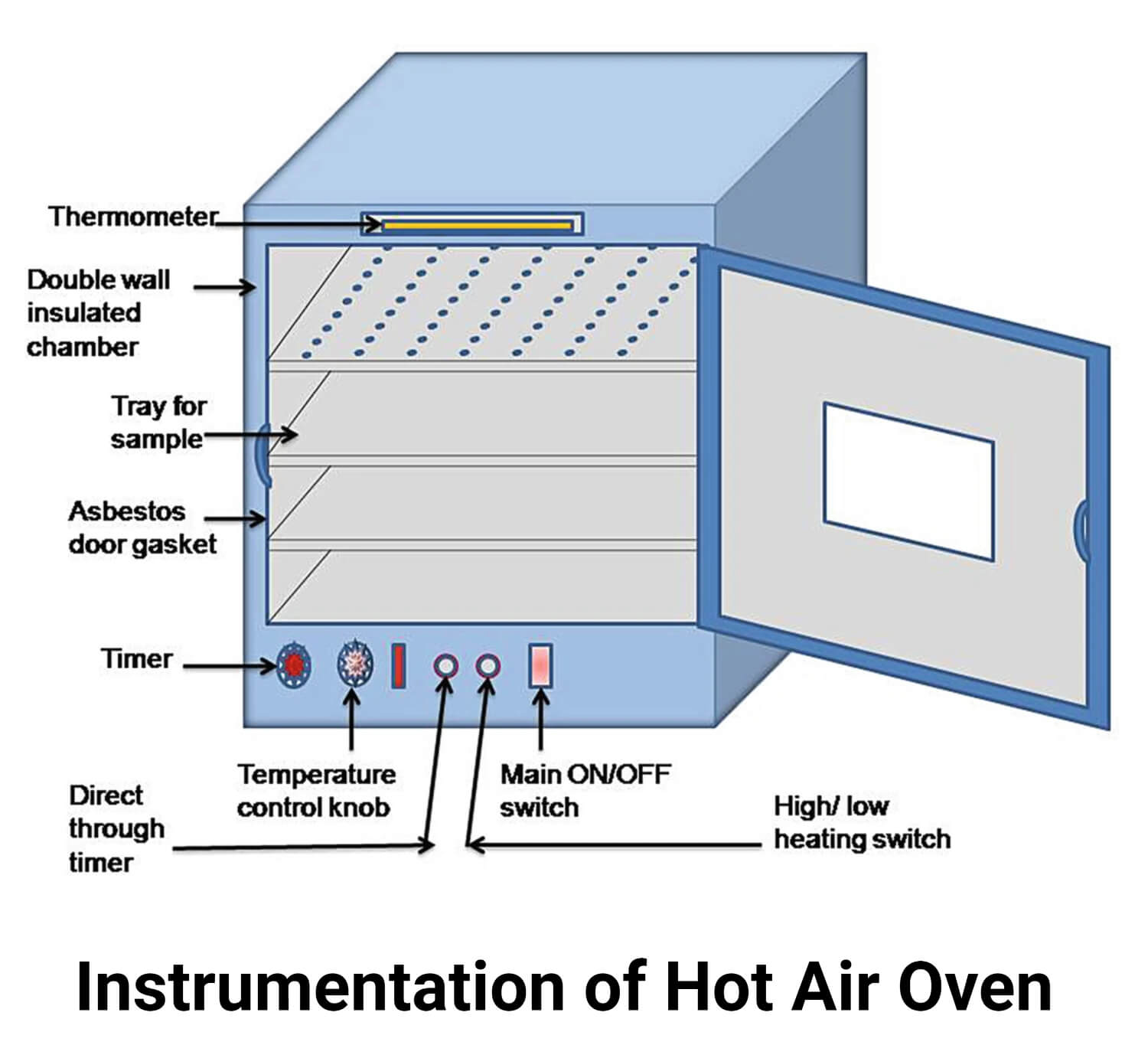

Instrumentation (Parts) of Hot Air Oven

Hot air oven comprises mechanical and electrical parts.

Mechanical parts

- Coat/Cabinet: The external shield is built of aluminum or stainless steel, which resists mechanical shocks and oxidation. It also insulates the internal environment from the external surroundings and prevents heat loss.

- Fibreglass: The space between the outer cabinet and inner chamber is filled with thick glass wool insulation. Two types of fiberglass are present, namely, brown fiberglass and yellow fiberglass. The latter is less dangerous compared to the former. Brown glass causes inflammation in the respiratory system, while yellow glass causes skin sensitivity. Thus it is preferred to use hand gloves while dealing with it. It also functions to prevent heat loss from the inside of the device to the outside.

- Chamber: The rectangular-shaped chamber is made of aluminum or stainless steel, which has space for ribs to keep shelves at the desired levels.

- Shelves (Mesh): These are objects holding plates and are made of aluminum. Depending upon the number and size of objects, as well as the oven capacity, their number may vary. When they are placed on the ribs, the movement of air is facilitated by lifting some areas. Also, some shelves may contain openings for aeration.

- Motorized fans/ blower: The fan is driven by the motor and is used to distribute hot air inside the chamber evenly.

- Door: A single door on one side is fitted on the heavy hinges. The presence of an asbestos door gasket on the side is used to decrease heat loss during the operation.

Electric parts

- Power supply: The power supply is done with the use of a 220V-50Hz transformer and rectifier.

- Heater: With the passage of electric current through a conductor, heat is generated following the rise of temperature. The heating element has three main features: high resistance, electrical insulation, and high thermal conductivity. The different types of heaters used in hot air ovens are One side circular type heater, One side U type heater, One side wave type heater, One side square type heater, Three sides type heater, and Four sides type heater. The heater operates at temperatures from 50 to 300 degrees Celsius.

- Thermostat: It is a heat sensor connected directly to a heater and can resist extreme heat with a high negative temperature coefficient. It facilitates users to obtain the desired temperature in the hot air oven and prevent temperature overshoot.

- Temperature indicator: Either a thermometer or thermocouple can be used to determine the internal temperature of the oven.

- Timer: There may be two types of timers: Electrical or Mechanical, which can operate for 5-60 minutes given the time period for sterilization.

- Fuse: Fuse functions to prevent electrical damage due to high current during short circuits or high loads.

- Control Panel: It is the region that allows the user to control different parameter settings such as temperature, time, etc., as well as has an indicator power lamp (usually green), indicator heater lamp (usually red), and switch knob.

Types of Hot Air Oven

Natural convection oven/ Gravity convection oven

It operates on the principle of natural convection in which the heated air at the bottom of the device rises towards the ceiling, where it starts to cool and again descends toward the floor such that the cycle of heating and cooling continues within the device naturally. It has no uniform distribution of temperature and is suitable for powder samples.

Forced convection oven

The forced convection oven employs a motorized fan/blower to force the hot air to distribute uniformly throughout the entire interior of the chamber. It allows the sample to absorb heat and dry faster since they are always in contact with hot air.

Side draught oven

It has a unidirectional flow of air from one side to the other such that samples achieve maximum heat absorption in a short time. It is ideal for preheating plastic clothes in hospitals or smooth sheets or plates.

Hot Air Oven Operating Procedure

Here are the steps of operating a hot air oven:

- The oven is plugged into the socket and switched on.

- The oven is preheated for 30 minutes before placing the items on the trays or shelves.

- The temperature gauge is set at the desired time, depending on the volume of the contents to be sterilized.

- The items are loaded on the shelves (appropriate spacing should be maintained between the articles on the trays for efficient heat circulation).

- The door is closed by fastening the screws provided, after which the temperature begins to rise.

- It is better to have sound knowledge of the sterilizing holding time and temperature of the hot air oven. The thermometer is checked in to determine whether the desired temperature is achieved after a certain holding time.

- The device is switched off once the temperature holding period is achieved, allowed to cool down before opening the door, and then the samples are removed using oven mitts or tongs.

- The door is closed after removing the samples.

Applications of Hot Air Oven

Some of the applications of hot air ovens are:

- It is used for sterilization of laboratory equipment such as glassware (flasks, pipettes, Petri-plates, and test tubes), culture media, metal items (forceps, spatula, scalpel, scissors), non-volatile compounds (zinc and starch powder, sulfonamide), and other materials that contain oils.

- It can be employed for testing food items, pharmaceutical products and other consumable materials in order to ensure their temperature stability during the shelf life.

- It can be used in research settings in the field of biology, chemistry and material science.

- It can be used in heat treatment and drying of samples, such as metals, alloys, soil, and other materials.

Advantages of Hot Air Oven

- It does not require water for sterilization purposes like an autoclave.

- It is economical and easy to operate.

- It can function at higher temperature and faster than autoclave.

- The small size of the oven requires less space and has an easier installation process.

- The dry heat does not corrode or rust metals or other sharp articles.

- It is smaller in size and is convenient to work on.

- Less pressure built in it ensures safety during operation.

- It is non-toxic. No harmful chemical residues will be discarded.

- The dry heat can penetrate deeply into thick objects such that it helps to achieve an in-depth sterilization effect.

Limitations of Hot Air Oven

- It is not suitable to sterilize items such as rubber, plastics, surgical dressing, etc., due to their low melting point.

- It may not destroy the heat-resistant endospores and prions because they utilize dry heat instead of moist heat.

- It is time-consuming relative to steam, flaming, chemical sterilization, or radiation.

Precautions

- Only materials that are compatible with dry heat sterilization should be used. Combustible items are strictly prohibited from sterilization in a hot air oven.

- The items should be wrapped in paper or newspaper and placed in a cardboard or metal container. Cotton wool can be used to plug in test tubes, flasks, and pipettes.

- An individual must wait before opening the door so that the oven is allowed to cool up to 40°C. This prevents glassware breakage.

- Thermal gloves or tongs should be used to remove items from the oven.

- The oven should never be overloaded.

- The articles should be placed on shelves at proper spacing so that there is an un-interfered circulation of hot air.

Hot Air Oven Examples

Heating Oven EG (Steelco SpA)

- Availability of single or double-door pass-through hinges.

- The volume of the chamber ranges from 330 to 10,000 liters. However, it is customizable depending on the customer’s requirements.

- It has high performance, reliability, and efficiency with reduced energy and time consumption.

- The self-washing system can be installed for the Clean-In-Place (CIP) of the chamber and air ducts.

- The temperature range is 50 °C – 160 °C.

Heat Oven FAC-100 (Tech-Lab Scientific Sdn Bhd)

- Presence of a microprocessor-PID controller to maintain and achieve the desired temperature.

- Adjustable stainless-steel shelves and double-walled chamber with fiberglass insulation in between.

- The capacity of the chamber is 100L, with an operating temperature range between 5 °C – 220 °C.

Sterilization Oven FN series (Nüve)

- The triple insulation comprises glass wool, an aluminum layer, and an air gap. It ensures high efficiency and reduced energy consumption.

- Uniform temperature can be maintained throughout the chamber by natural air convection.

- To minimize temperature loss, the door can be pressed tightly on the chamber gasket.

- FN series facilitate dry heat sterilization in medical, veterinary, dentistry, and research settings.

Heating Oven WHL, WHLL series (Tianjin Taisite)

- WHL and WHLL series are equipped with removable shelves, air duct lateral plate, stainless steel inner chamber, and bottom heater covering.

- Door is provided with a double-glass observation window, silicon rubber seal, and air-tight buckle lock.

- The temperature controller facilitates protection from over-temperature and employs a dual digital tube display to read the temperature.

Heating Oven 101A series/ 202A series (Zhejiang FUXIA Equipment Co., Ltd)

- Its small size enables working in small spaces.

- The glass observation window allows the user to watch the heating in the room.

- The inner chamber is built of cold rolled sheets of high quality.

- It features high stability, rigidity, strength, earthquake-resistant operation, and corrosion resistance.

References

- Alkadhim, Saif Aldeen Saad, Hot Air Oven for Sterilization: Definition & Working Principle (December 14, 2018). Available at SSRN: https://ssrn.com/abstract=3340325 or http://dx.doi.org/10.2139/ssrn.3340325

- https://www.laborildam.com/en/category/cell-theraphy-gmp-glp/natural-convection-type-ovens

- https://labproinc.com/blogs/laboratory-equipment/how-do-laboratory-forced-convection-ovens-work

- https://tempoinstruments.com/blog/hot-air-oven-guide/

- https://biologyreader.com/hot-air-oven-sterilization.html

- https://www.prestogroup.com/articles/what-is-the-use-of-hot-air-ovens-in-the-microbiology-industry/

- https://study.com/academy/lesson/hot-air-oven-for-sterilization-definition-working-principle.html

- https://www.mysticmedicalstudy.com/2020/07/sterilization-disinfection-physical-method.html

- https://www.medicalexpo.com/prod/steelco-spa/product-70928-832558.html

- https://www.medicalexpo.com/prod/tech-lab-scientific-sdn-bhd/product-121644-943725.html

- https://www.medicalexpo.com/prod/nueve/product-69565-608291.html

- https://www.medicalexpo.com/prod/tianjin-taisite/product-74814-648507.html

- https://www.medicalexpo.com/prod/zhejiang-fuxia-equipment-co-ltd/product-122147-931405.html

hi, I am Reagan from Uganda and i have a company that does electronics. I would like to learn something from you about an oven.

I am Ashley from Kenya studying Biomedical Engineering. I would like to like ask for work at your company or even as an intern